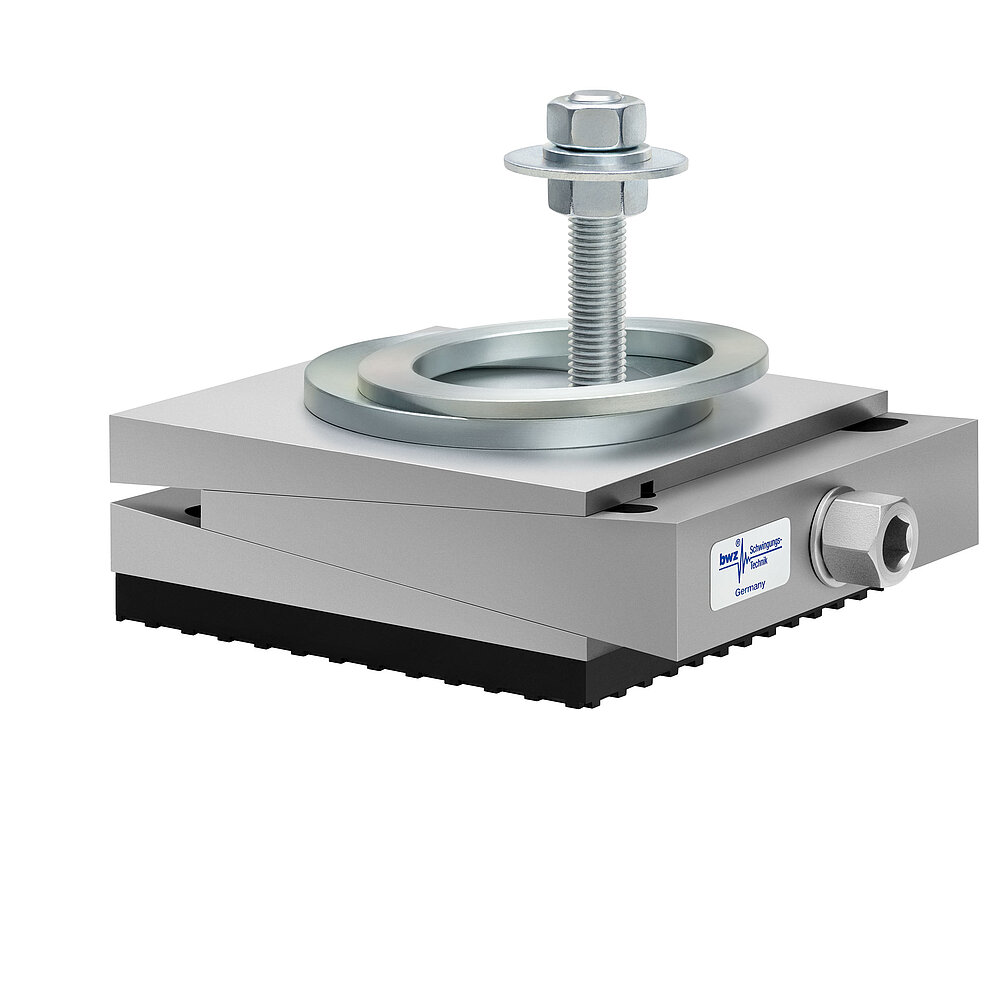

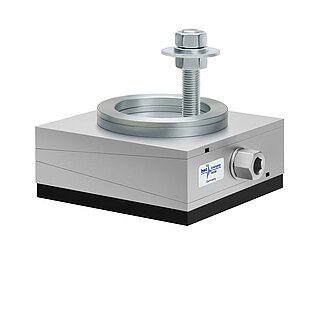

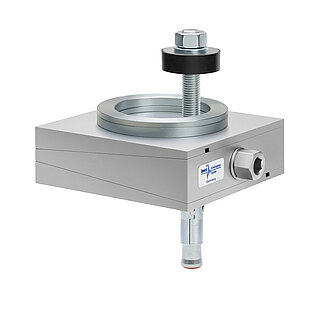

precision wedge mounts bolt-on (BO) with calotte - assembly instruction

We kindly ask to read the below carefully prior to assembly / installation of the precision wedge mounts.

The load data given in the precision wedge mount catalogue are valid for static load.

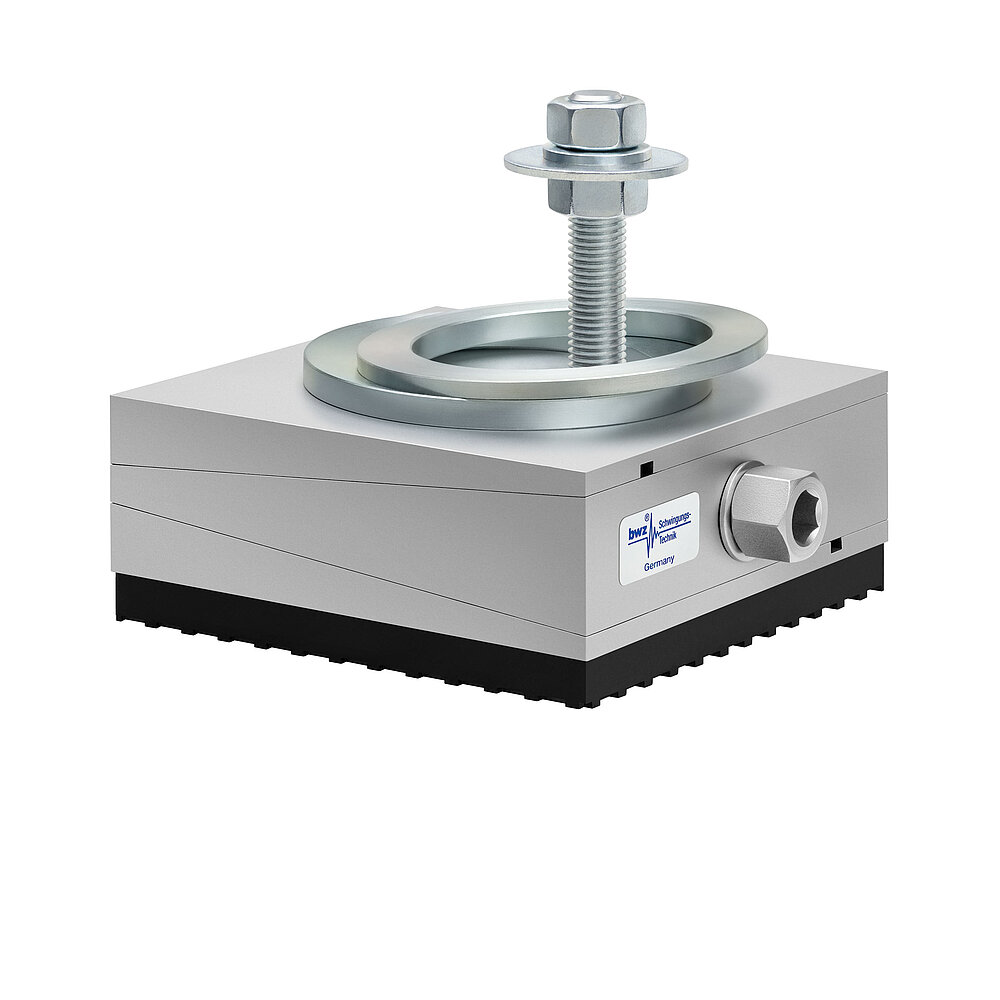

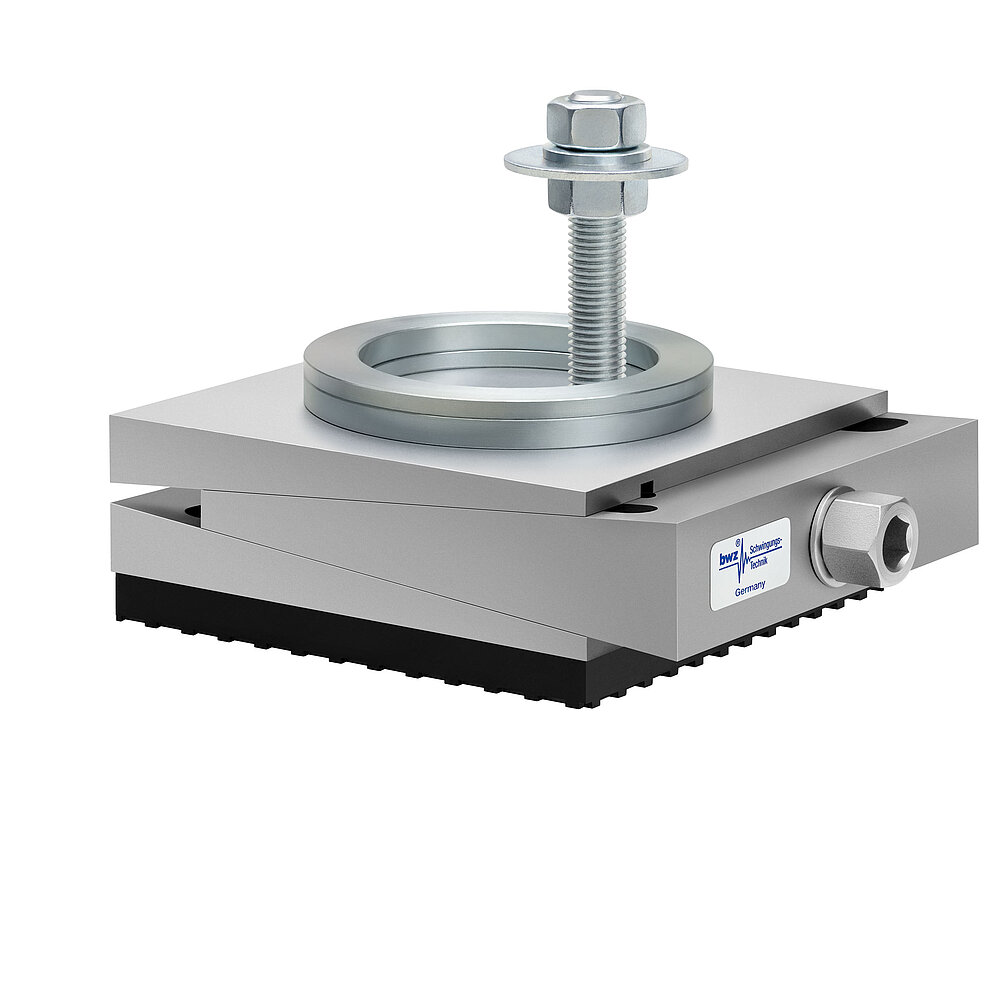

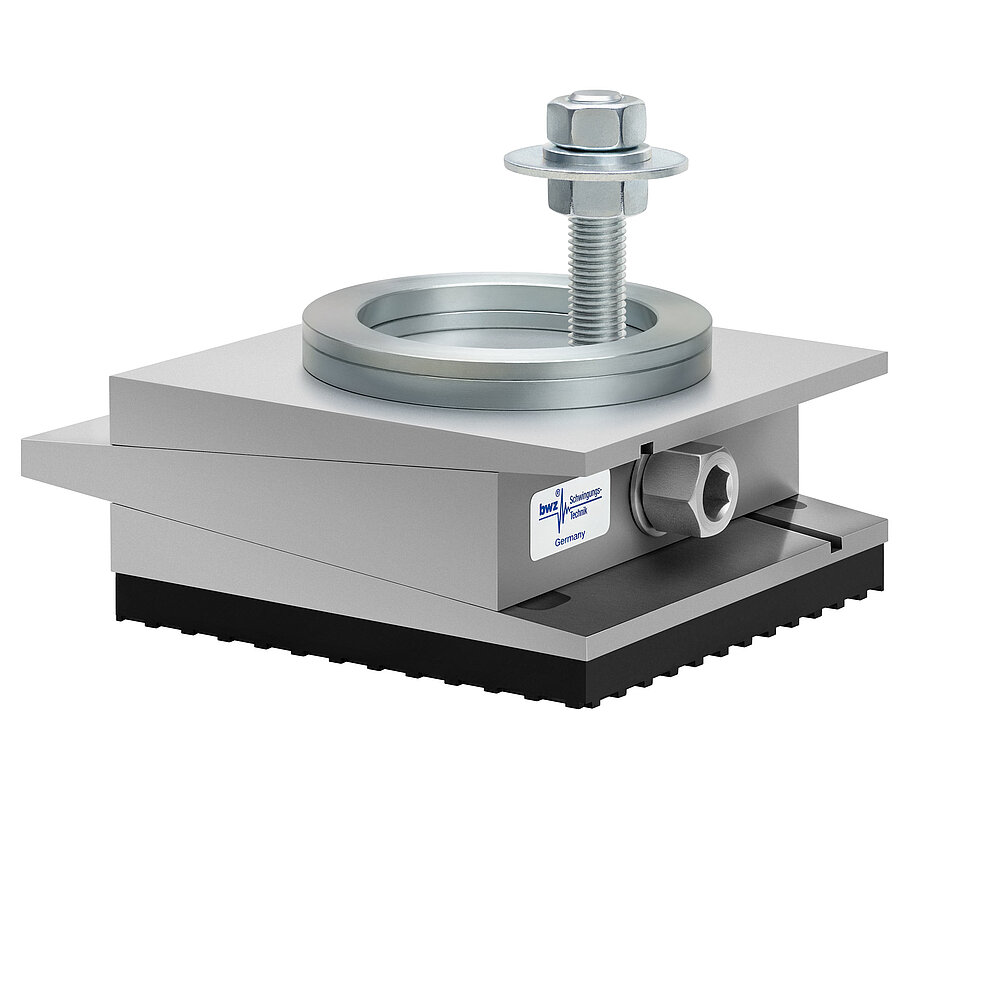

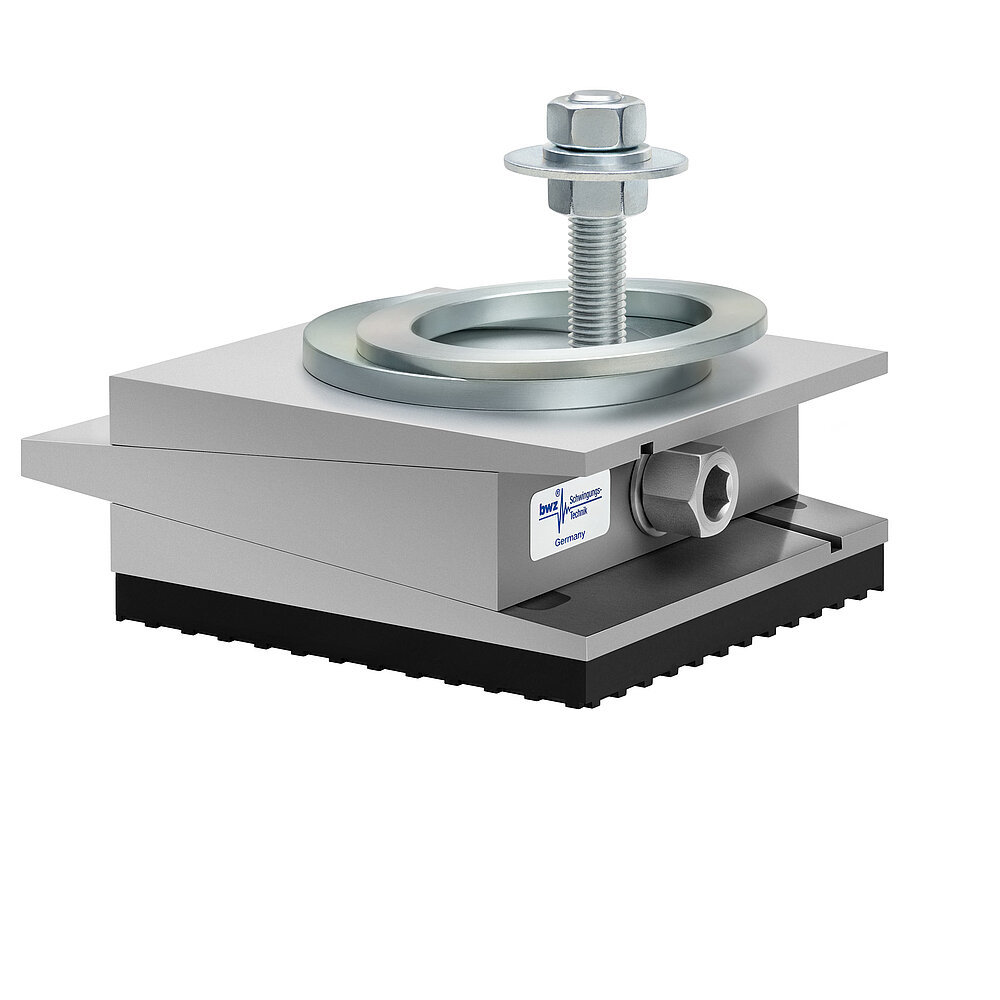

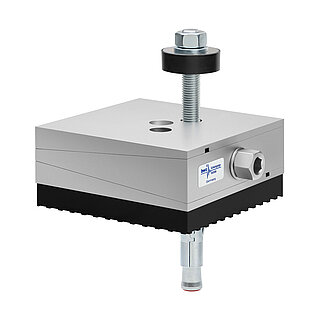

Height adjustment under load can be facilitated with highly reduced torque by adjusting from the top-most levelling height of the wedge mount downwards and thus making use of gravity. Prior to assembly / installation, we recommend to adjust the wedge mount to the top-most levelling height. In operation, the ideal levelling height to be achieved is the middle levelling height.

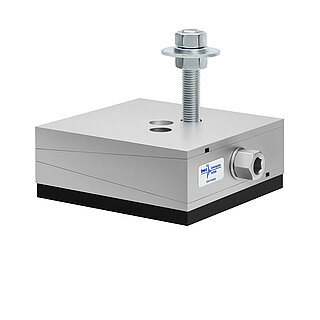

All parts have to be aligned interlockingly with their respective guide keys and grooved keyways.

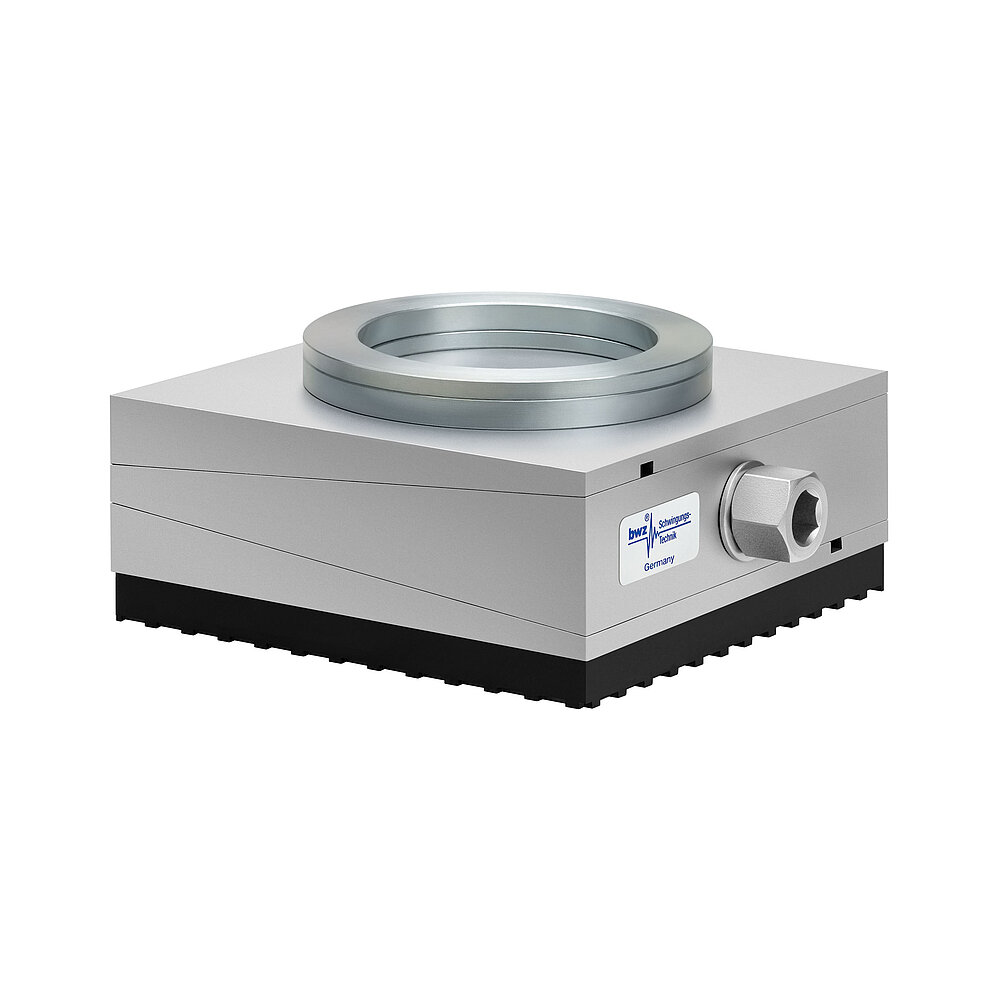

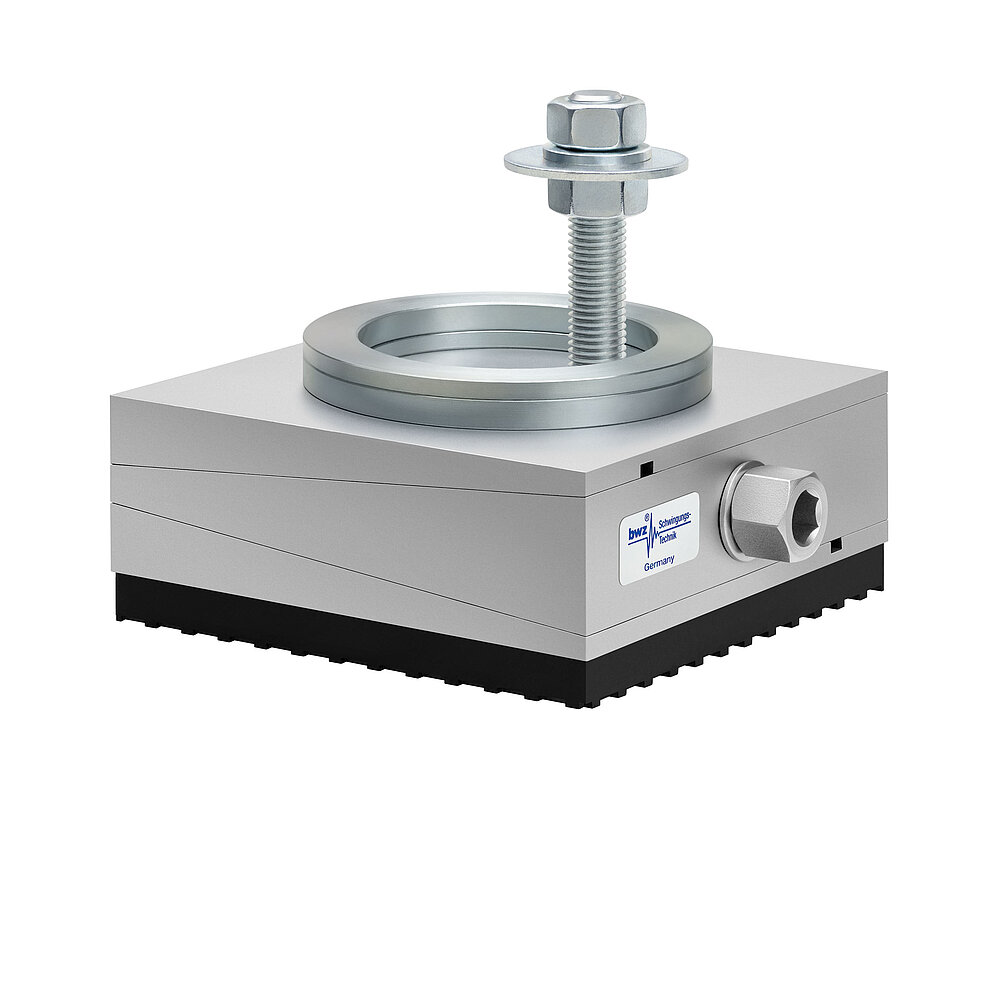

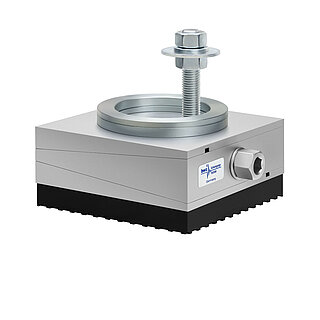

The precision wedge mounts bolt-on (BO) with calotte are designed for fastening with the machine frame and angle compensation. During transport, the wedge mounts are carried along, fixed underneath. Depending on the application, the bottom is equipped with a dampening or non-slip protection board of various shorehardness and optional surface structure.

In operation, the wedge segment with the dampening or non-slip protection board and the inner threads faces downwards, the wedge segment with the two-piece calotte faces upwards. The bolt-on screw is to be inserted no further / deeper than the adhesive-stuck elastomer board allows for.

The bolt-on screw must be fastened to the machine frame only after completion of the levelling process. Non-adherance to the above will result in the destruction of the middle wedge.

As described above, height adjustment is facilitated starting from the top-most levelling height, proceeding downwards.