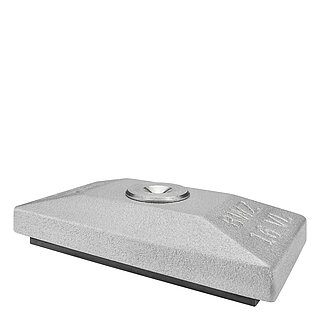

iron-cast levelling element

type V

A combination of square-shaped iron-cast base and non-fixed levelling screw with 120° tip and square shaft in zinc-galvanized version for an economic installation, levelling and vibration-isolated mounting of machines and devices.

- suitable levelling screws

- with 120° tip and square shaft in zinc-galvanized version in the selection list

- stainless steel levelling screws on request

- standard colour of the iron-cast base

RAL 9006 white aluminium

other colour tones according to RAL on request - optional ( at extra charge )

- special electro-plating for the iron-cast bases and levelling screws in nickel or chrome

- individual packaging of levelling elements in quick-lock mechanism bags

- customized article labelling